Tubing

-

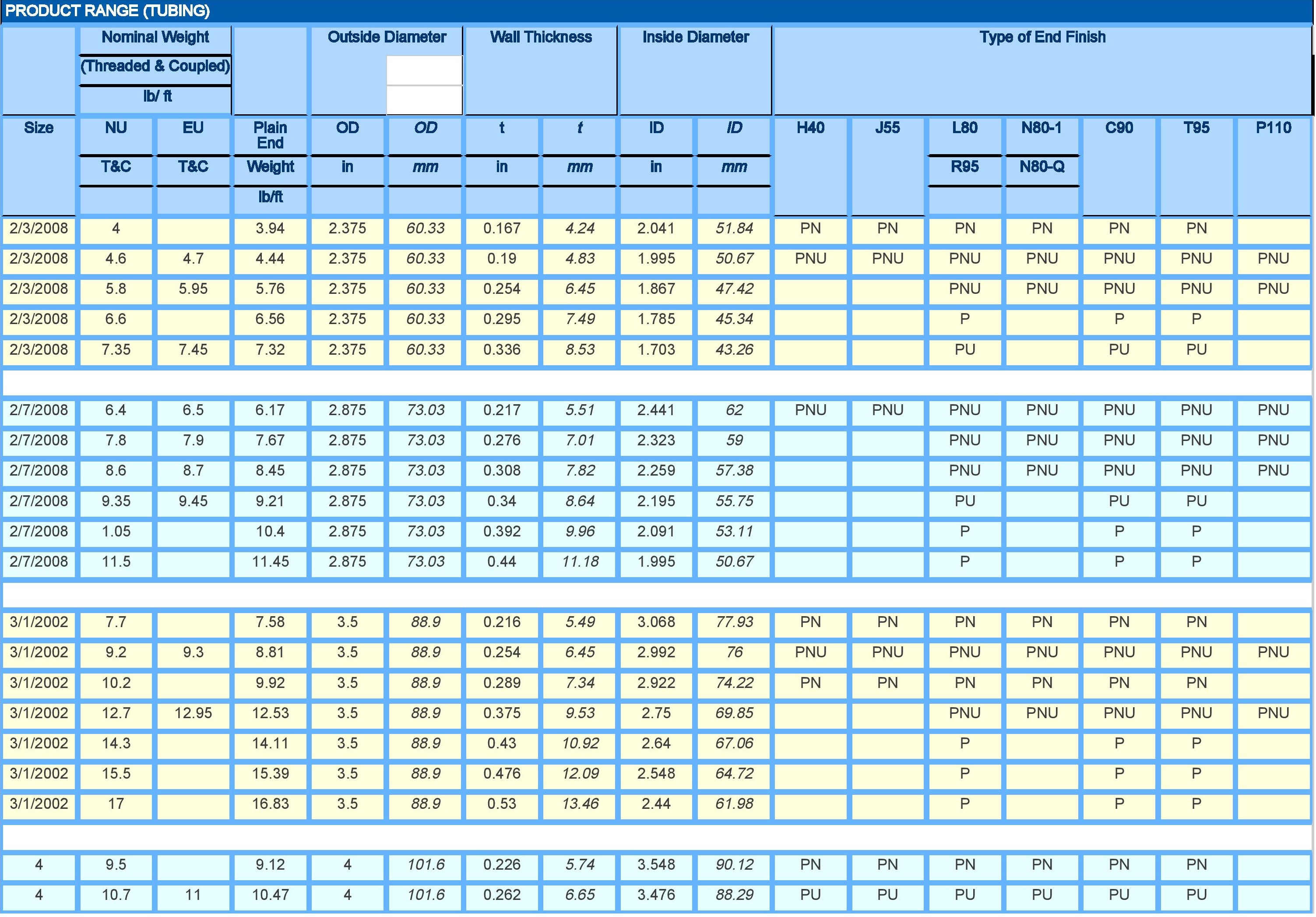

Yakun marketing offers the complete range of API Tubing from 2 3/8" OD to 4 1/2" OD according to API Specification 5CT (Product Specification Levels PSL-1, PSL-2, PSL-3) and Premium Connections.The Premium Connections include Two Step Premium Connections

The finest quality steel is used for processing of Tubing & each step of the process is performed with the highest degree of accuracy to meet or exceed API Specifications as well as the Industry Standards.

-

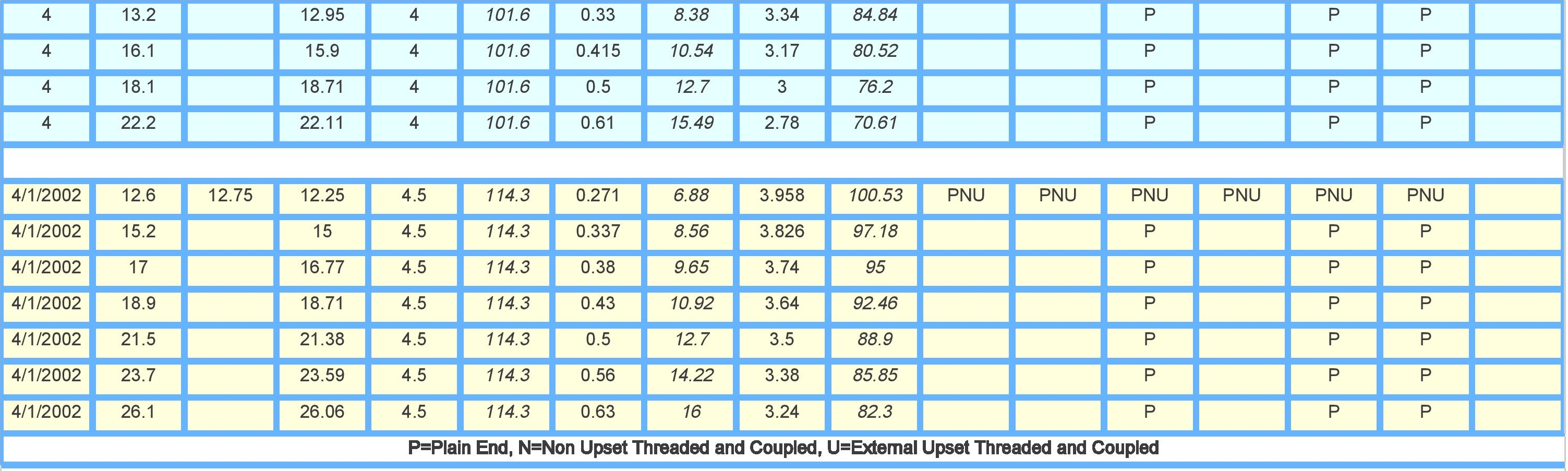

Plain End Pipe and Coupling Stocks in green condition ( un-heat treated) are ordered to specific metallurgical chemistries and dimensional requirements from reputed API Approved Mills only. Plain End Pipe is upsetted (where required) and heat-treated by Quench and Temper process. Each Heat Lot is tested for mechanical properties. The heat treated Tubing is 100% inspected nondestructively prior to threading. The Coupling stock follows the same process prior to threading.

-

The threading on the Pipe and the Couplings is done on CNC machines and 100% gaging of all the critical dimensional parameters is done and recorded. The finished Couplings are given anti galling treatment (Zinc or Manganese) prior to Buck-on operation.The Couplings are Bucked-on to the pipe at their specific designed buck-on torques which are recorded.All Tubing are subjected to Hydrostatic Testing as required by API Specifications.Internal Plastic coating of tubing can also be provided at customers option.The finished Tubing is externally coated with rust preventive varnish, attached with Thread Protectors and Skid Bundled with utmost care.

PRODUCT RANGE TUBING