Heavy Weight Drill Pipe

-

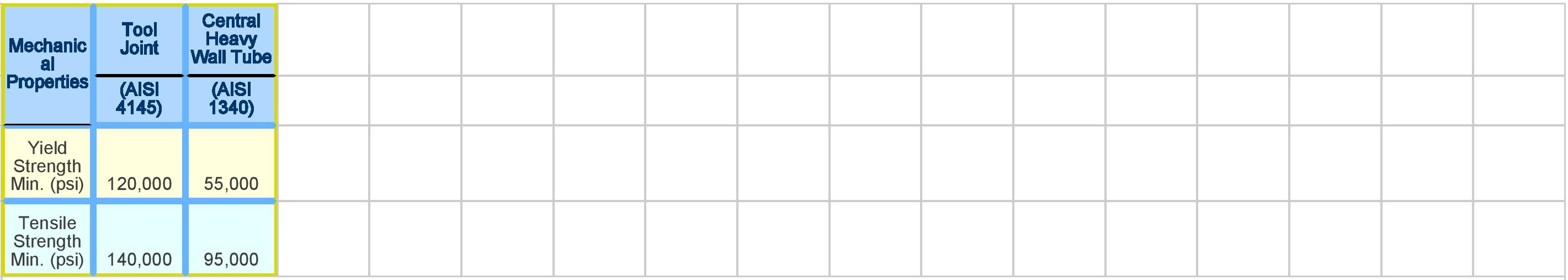

Heavy Weight Drill Pipe consists of two extra long tool joints and one central heavy wall tube. The tool joints are friction welded to the central heavy wall tube. The tool joints are manufactured from AISI 4145 H modified material, fully heat treated to 285 _ 341 Brinell hardness and 40 ft-lbs. minimum Charpy V-notch Impact strength. All other physical properties conform to API 7-1. The central heavy wall tube is AISI 1340 steel or equivalent.

-

Yakun Marketing also offers Integral Heavy Weight Drill Pipe.

-

Standard hardbanding includes one 4" wear pad on both pin and box end, plus one 1" pad on taper section of box to prevent fluid cutting and two 3" wear pads on central upset to prevent wear on the pipe section. The hardbanding is completely flush on both tool joints and 1/8" oversize on the central upset (fully flush on request). Hardbanding materials include crushed sintered tungsten carbide of 14-24 mesh, SmoothX©/Super SmoothX©/CASING PLUS©/Arnco 100XT™/Arnco 150XT™/Arnco 300XT™/Arnco 350XT™/ARMACOR M™/TCS™ Titanium/TCS™ 8000/Duraband© NC/Tuffband© NC.Internal Plastic Coating, if required (optional).

-

Spiral Heavy Weight Drill Pipe:

Spiral Heavy Weight Drill Pipe consists of three spiral upsets equally spaced between the tool joints. Spiral Heavy Weight Drill Pipe features more weight per foot and better hole cleaning characteristics than Slick Heavy Weight Drill Pipe, providing optimum performance in severe drilling conditions.

PRODUCT RANGE HEAVY WEIGHT DRILL PIPE

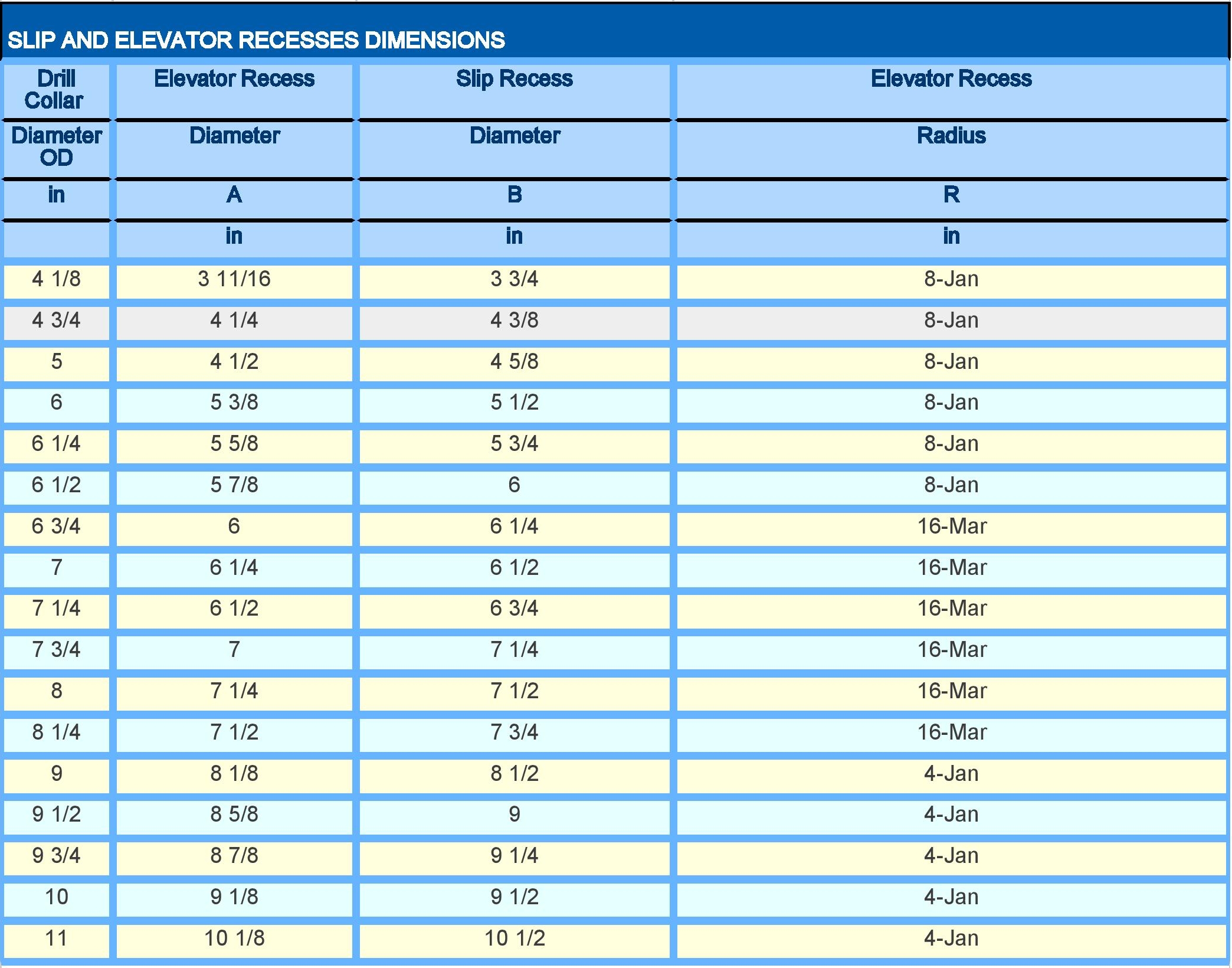

SLIP AND ELEVATOR RECESSES DIMENSIONS